'Hands-on Help for SMEs' and Smart Technical People'

3D Scanning for Engineers

Bringing physical objects into the 3D digital environment. Used during product development, for quality inspections and to digitally construct the factory environment

3D Scanning Reverse Engineering

3D Scanning Reverse Engineering

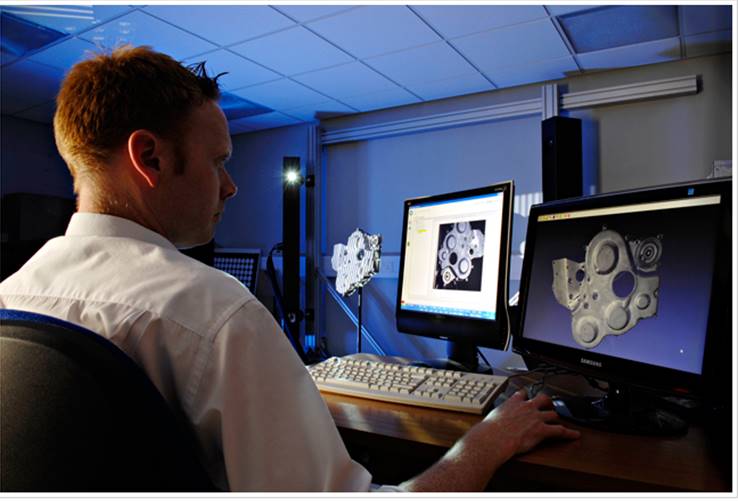

3D Scanning is increasingly being used by design engineers and technicians to speed up decision making in the product development process or when planning factory layouts and operations. During design development, 3D scanning reverse engineering involves capturing information about existing physical parts and recreating them digitally in a virtual environment. Dimensionally, the process is highly accurate.

A range of methods exist to measure objects during 3D scanning. They include laser scanners, light scanners, coordinate measurement machines (CMMs) and industrial CT scanners. Raw measurement data is normally collected as point cloud information which then has to be transformed into a more usable format such as a mesh or CAD model. Typically scanning equipment is used in conjunction with reverse engineering software to achieve this.

Reverse engineering is used to scan physical parts for which sometimes no drawings or CAD data exists, and so recreate digitally usable information. This is ideal for recreating spare parts, replacing worn or damaged components or for assessing competitor products to better understand their make-up and costs.

Quality Assurance and 3D Scanning Reverse Engineering

Quality departments are also using CAD data by measuring and comparing physical products with digital files. Component geometric dimensional accuracy can rapidly be measured and validated, before being documented in a report if necessary. This is particularly useful for parts with complex geometry, worn or damaged tooling or moulds, or for analysing the accuracy and build quality of assemblies, for example checking for fit, gaps and alignment. From a business perspective you get better RoI on the cost of your CAD if it's used in multiple stages of your development and manufacturing process.

Production-based 3D Scanning

Factory scanning is becoming increasingly popular as a way of quickly capturing and recreating the manufacturing environment in a virtual world. This enables effective production plant planning, including the positioning of machines, services, maintenance and ergonomic human interaction. Additionally, robotics and automation can be planned out digitally to ensure efficient production processes, before the expensive and logistically challenging work of fitting physical plant begins. Some software will plot your 3D factory scans onto your 2D production floor plans, enabling you to rapidly recreate your virtual industrial environment.

This page looks at how 3D Scanning can be utilized by small technical businesses. Used in conjunction with other technologies like CAD, 3D printing and computer aided manufacturing (CAM), 3D scanning enables you to digitise the complete design and production process. This is achieved by bringing the physical world into the digital environment, before making design modifications and finally outputting real components.

Below you’ll find examples and case studies, a comparison of scanning equipment, practical reverse engineering explanations, scanning software, as well as how 3D scanning is helping engineers’ layout factories and achieve efficient production.

As ever, try to visualise how some of the examples below could be applied where you work, to speed things up, professionalize what you do and ultimately create bottom-line benefits

Enjoy!

Mark Lynch

Advice Manufacturing

3D Scanning for Reverse Engineering (Courtesy of Exact Metrology)

Replacing calipers and those long, drawn-out periods spent actually creating CAD drawings, 3D laser scanning is a fast and incredibly accurate way to obtain and use CAD data on parts of nearly any size. In the video above, we explore the advanced capabilities of the ROMER Absolute portable CMM arm with an integrated laser scanning head. Watch to learn more.

Reverse Engineering Services Using 3D Scanning (by 3DEng Solutions)

3D Engineering Solutions provides reverse engineering services by using advanced 3D laser scanning technology to create 3D CAD models directly from physical parts.

Reverse Engineering Parts using a Cabinet Scanner (by Roland DGA)

With the touch of a button, Roland LPX DS Series 3D laser scanners can generate a detailed, high resolution 3D model with watertight surfaces. Optional Pixform Pro II reverse engineering software enables users to quickly and intuitively convert scan data into fully editable 3D CAD models.

Reverse Engineering a Large Gear (courtesy of DeWys Engineering)

Here we see the process of 3D laser scanning a large gear from a foundry gear box that was worn out. A 3D point cloud was scanned into Geomagic Design X using a Faro Platinum Arm with a V3 LLP. After all the data was captured and holes / slots probed a solid 3D CAD file was generated in Design X, then exported into Soildworks where it was detailed, and finally, reproduced on a gear hobing machine.

Go!SCAN 3D scanners: The easiest 3D scanning experience, generating fast and reliable measurements - by Creaform

Through a very efficient process, these self-positioning systems can be used by anyone without requiring any prior experience or background, and provide visual guidance as you are scanning. With these handheld 3D scanners, you can even capture 3D data in full color.

3D Scanning Reverse Engineering

A Guide to 3D Measurement Technologies (Courtesy of Develop3D)

Any company designing or manufacturing products with complex geometries will at some stage have a requirement to accurately measure either prototypes or finished products to ensure they meet design parameters.

The range of equipment available for this is ever-increasing, but is based around three main system types – point-based systems, consisting mainly of contact probes mounted on either a co-ordinate measuring machine (CMM) or measurement arm, and laser trackers; stripe-based systems, comprising mainly laser scanning systems; and area-based measurement systems such as white light systems. More...

3D Scanning Reverse Engineering

Capturing Reality: A Guide to Hardware (Courtesy of Develop3D)

In the world of reverse engineering there’s a huge range of technology and processes to capture the form, geometry and nature of physical objects. These can be design concepts, existing components or conceptual models. There’s a bewildering array of products, processes and workflows available from a range of vendors. More...

3D Scanning Reverse Engineering

Factory Scanning Applications

Web-Based Factory Laser Scanning and CAD Integration by PMC

This video demonstrates integration of CAD tools and factory laser scan data. This simplifies the use of laser scans for all users. It's possible to quickly visualise factory layouts in 3D, from plans originally in 2D. Additionally, measurements between work stations and a range of other clever tools are incorporated.

Power Plant 3D scanning, Factory, Mill, Refinery by Arrival3D

Arrival3D can scan your existing plant in a matter of days and provide accurate 3D models of piping, structural steel, ductwork, equipment, and other fine details to allow you to engineer plant changes such as new pipe runs with the least intrusive path.