'Hands-on Help for SMEs' and Smart Technical People'

Embodiment Design:

Modular

Design and Product Architecture

Essential Product Development for Engineers

Modular design describes a situation where a product is organised into a number of assemblies, each one developed to complete a specific function. All assemblies (or modules) interact with each other to carry out the product’s overall purpose. Modular product design is part of a wider theoretical product development topic, known as product architecture.

Product Architecture

Product Architecture is concerned with how the function of any product is organised into physical parts, such as assemblies and components. As mentioned earlier, the overall function of the product is reviewed and a number of sub-functions are identified, which need to take place in order to achieve the overall function. Likewise, assemblies and parts must be assigned to carry out these sub-functions and in-turn the whole function. There are principally two types of product development architecture – integral design and modular design.

Integral Architectural Design

Integral design describes an arrangement where the functions of the product are undertaken by a range of parts, not necessarily arranged or organised in assemblies. The product is arranged in a less structured, logical layout than modular design. A consequence of this is any modifications to components tend to affect most parts around them. Clearly, this has cost implications for maintenance and servicing. Also as products are developed separately and independently, parts and groups of parts are far less interchangeable than with modular design. Again there can be cost implications as unique arrangements and parts take longer to assemble and can be costly to source.

Modular Architectural Design

Modular design identifies particular functions (or individual operations) necessary to achieve the overall product purpose. Standard assemblies are then developed to undertake these individual operations. Subsequently, the assemblies or modules are brought together to form the complete product, which can then perform its complete function. The assemblies have standard interfaces with each other. With modular design, assemblies are treated like individual components.

During Detailed Design (the next stage of the product development process), technical information about each assembly is understood and documented. As well as function, this includes physical measurements, specifications, reliability, cost, services etc. This makes it possible to select and purchase assemblies in the same way as components are procured, particular if some of your product range have common functions.

Cost-wise, clearly this makes sense, as parts that make up an assembly can be purchased in greater numbers for less, as more are required. It is also a good design decision to select something of known quality, reliability etc. Personal computers are a common example of modular design. Here almost anybody can combine modules which perform different functions (and manufactured by different companies) to build computers cheaply, that perform an overall function.

Integration, compatibility and interfaces (where modules interact) are important factors in successful modular product development.

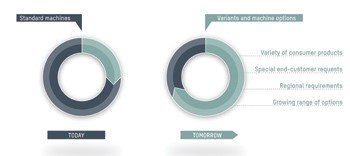

Modularity Makes Semi-Custom Machine Development Economic

Modular Machine Design Example and Report:

Industrial Technology & B&R Industrial Automation. More

Modular Design and Product Architecture Explained Simply

Next... Benefits of Modular Design including Modular Manufacturing

Back to Product Development Essentials

When was the last time your business developed a NEW product? ...Or is 'Product Development' too far removed from your core Production Engineering activities?

Does your firm have a clear product development process, with a number of new products released to date? ...Or alternatively, do you think bread and butter production engineering is really what matters? Tell us about your product development experiences...

Share your story...and receive a FREE copy of our report 'Helping Your Manufacturing Business Thrive'...

PS: Feel free to name-drop your firm! There's nothing wrong with a bit of free publicity!

What Other Visitors Have Said

Click below to see contributions from other visitors to this page...

Pre engineered steel buildings manufacturer Lebanon | dalalsteel.com Not rated yet

Dalal Steel is a leading manufacturer of pre-engineered steel buildings in Lebanon , providing durable and efficient solutions. Visit dalalsteel.com. …